Reset provides condensate stabilizers and fractionation units designed for maximum efficiency and flexibility. Our solutions ensure the highest recovery of valuable hydrocarbons from natural gas, optimized overhead compression power requirements, and precise separation allowing for the efficient isolation of valuable hydrocarbons.

Condensate Stabilizers Key Features

Fractionation Units Key Features

Specifications to Suit Your Needs

Our Condensate Stabilizers & Fractionation Units come in a range of sizes and capacities to meet diverse operational needs as well as bespoke sizes for unique applications:

- 2.5K bbl/d

- 4K bbl/d

- 5K bbl/d

- 7K bbl/d

- 10K bbl/d

- 12K bbl/d

- 15K bbl/d

- 20K bb/d

- 25K bbl/d

- Sized to Suit

Key Features that Set Us Apart

Get Started with Our Condensate Stabilizers & Fractionation Units!

Experience the difference that innovative, sustainable, and high-efficiency solutions can make. Let’s work together to enhance your gas treating process and achieve your operational goals.

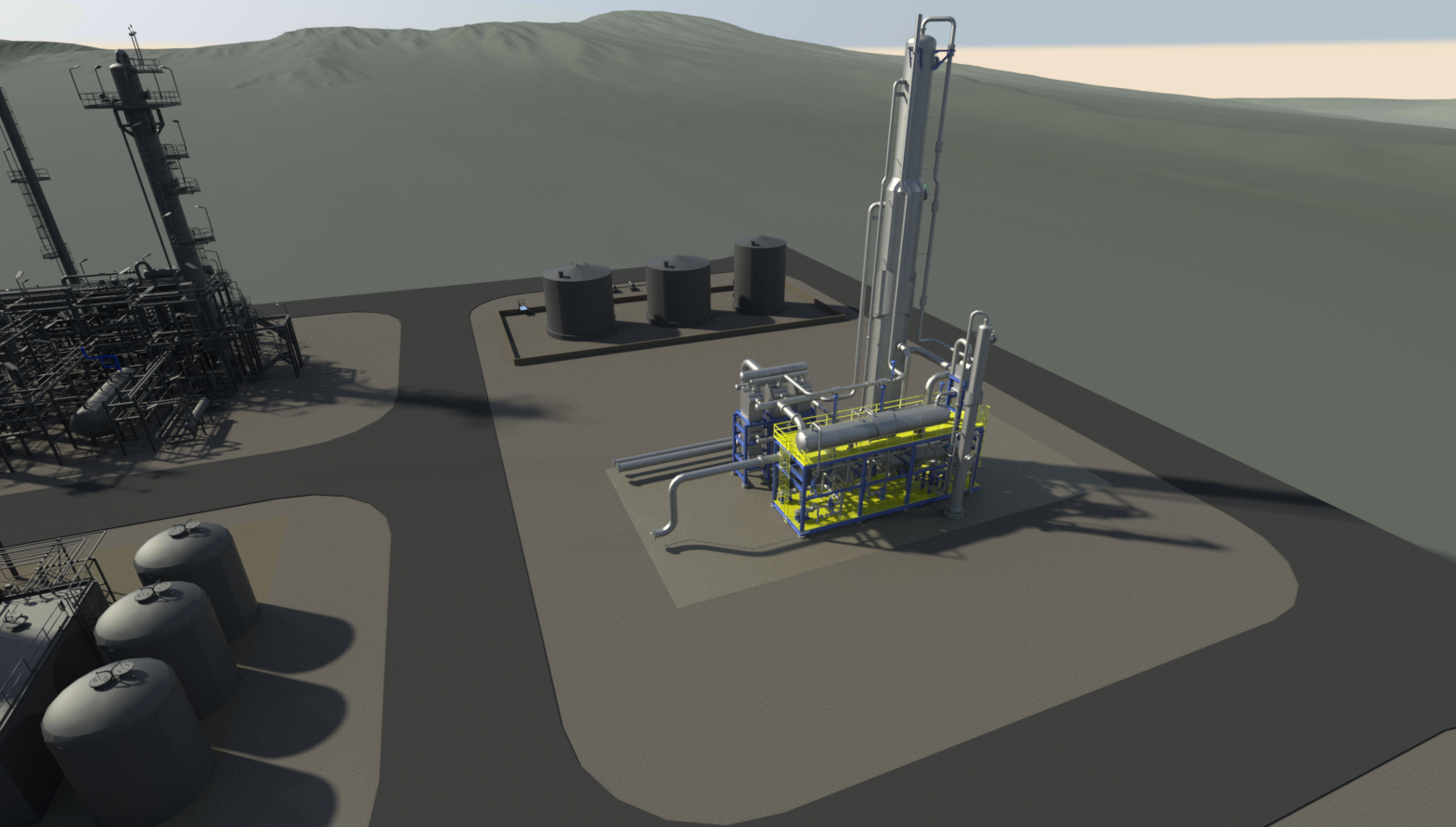

Our Projects

Two 400 GPM Amine Treaters, Two 2.5 MMBtu_Hr. TEG Dehydrators, One 5,000 BBL_D Condensate Stabilizer

1600 GPM Amine Treater, 3 MMBtu_Hr. TEG Dehydrator, 10,000 BBL_D Condensate Stabilizer

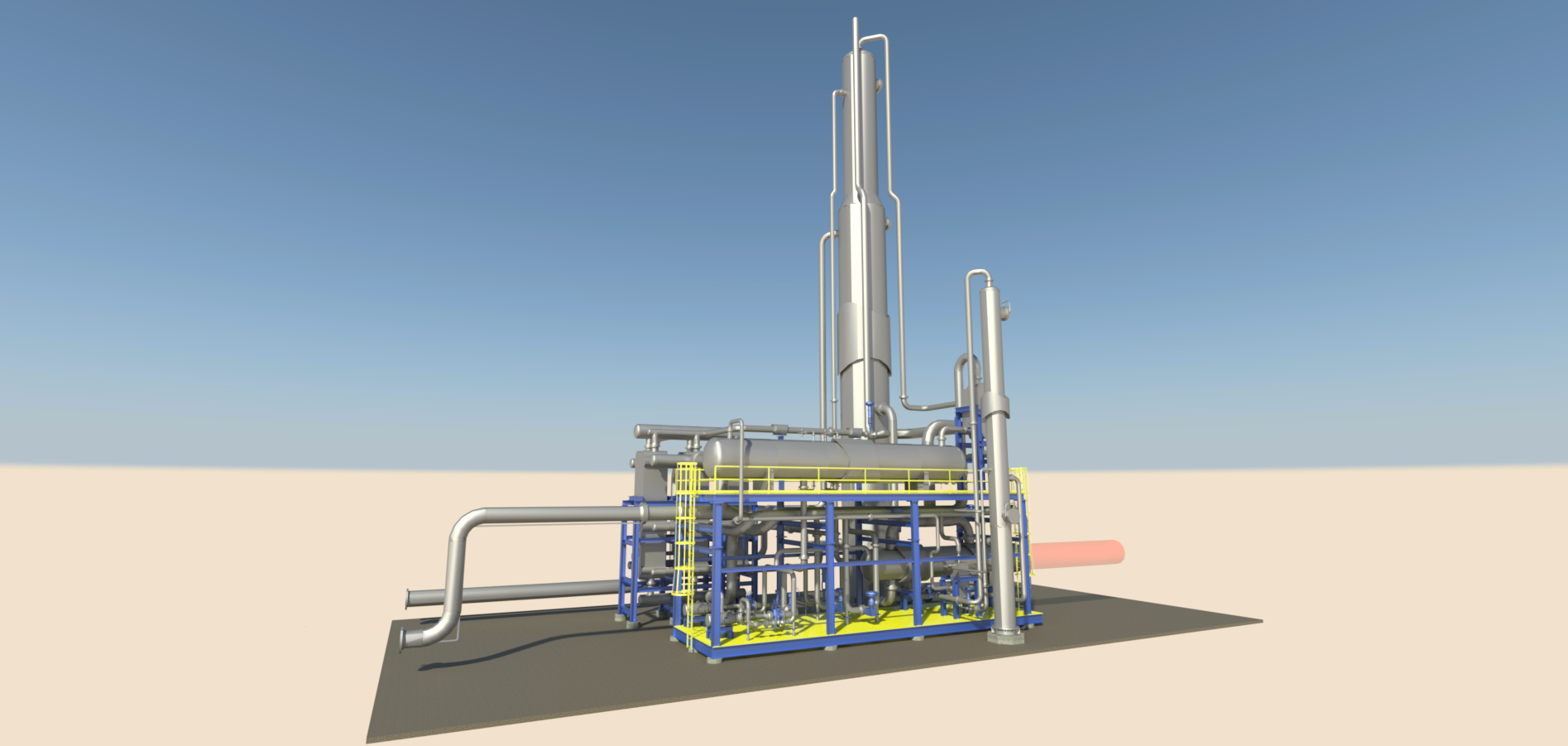

10,000 BPD Stabilizer Package

Experience industry-leading reliability and performance as we redefine gas treatment standards. Explore our transformative solutions today. Innovative gas processing & treatment solutions that solve complex energy challenges