Amine Treating With Reset Energy

Amine treating technologies offer a proactive approach to corrosion reduction by removing CO2 and H2S from the gas stream. These technologies utilize amines, which are organic compounds that react with and remove acidic gases from sour streams. By eliminating these contaminants, amine treating significantly reduces the potential for corrosion in downstream gas processing equipment and transmission networks.

The amine treating process involves several key steps:

There are various amine solutions on the market, and some of the most commonly used (generic) amines include:

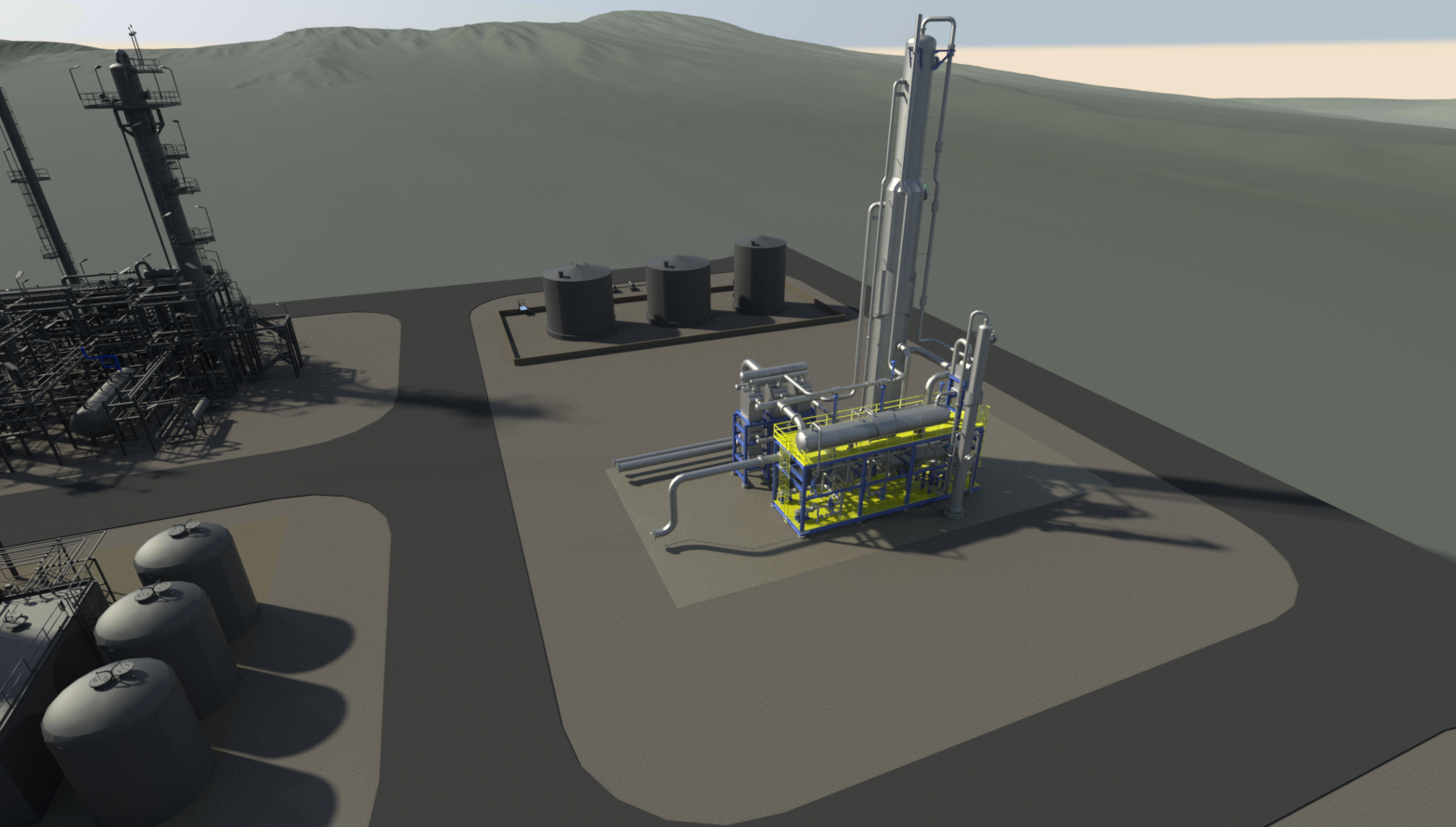

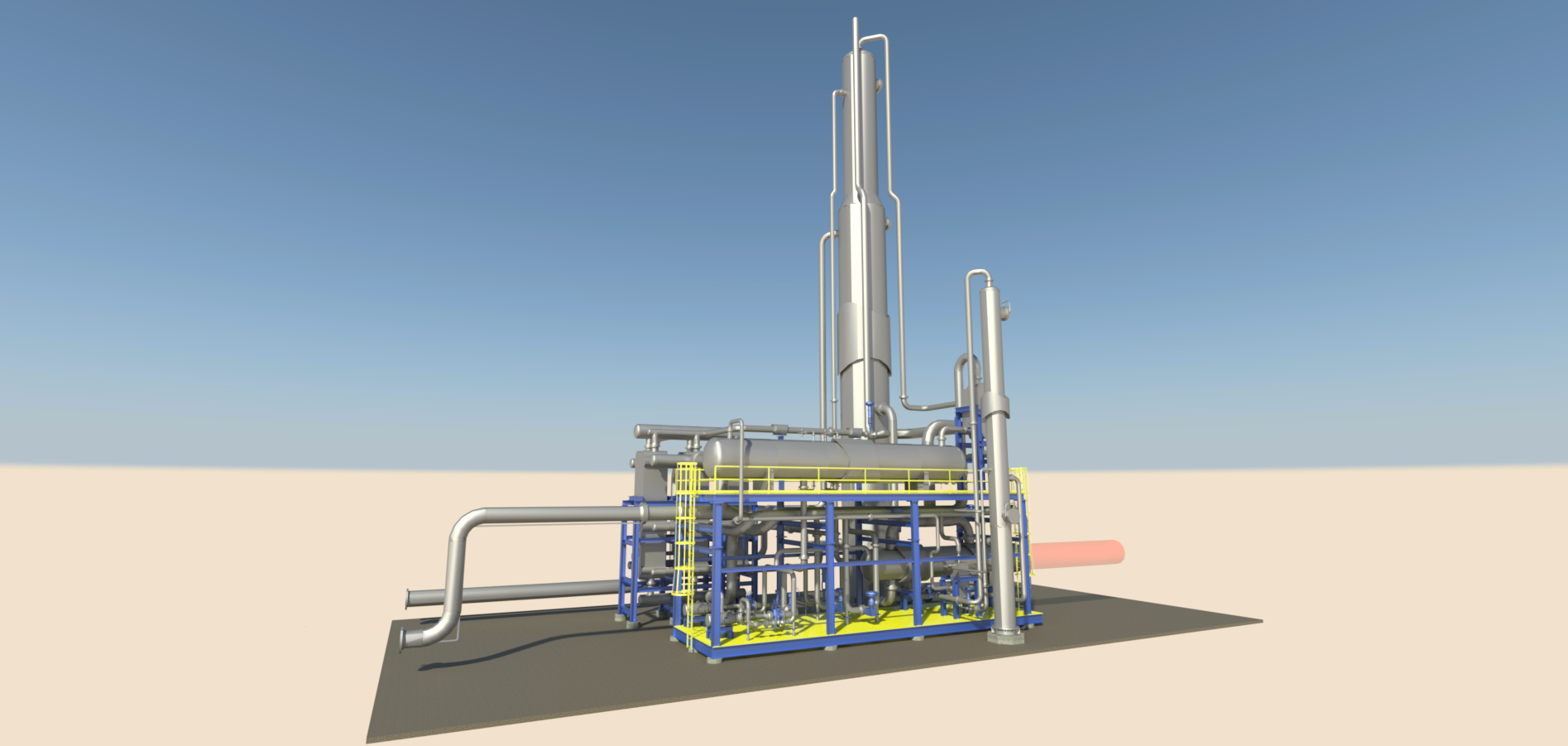

Reset’s Amine Treating Solutions

Reset’s advanced amine solutions are specially engineered to remove impurities such as hydrogen sulfide (H2S) and carbon dioxide (CO2) from natural gas and petroleum products. With a focus on flexibility, efficiency, and durability, our solutions are tailored to meet the dynamic needs of the oil and gas industry.

Our amine solutions are designed to handle varying compositions of acid gas and hydrocarbons. This high degree of flexibility allows for optimal performance across different gas processing environments, ensuring that impurities are effectively removed regardless of the feed composition.

Utilizing advanced separation designs, our systems ensure adequate amine and hydrocarbon separation. These designs are meticulously engineered to maximize efficiency and performance, providing you with a reliable solution that meets stringent industry standards.

To minimize amine degradation, our packaged process equipment solutions adhere to conservative skin temperature guidelines. By maintaining appropriate temperatures, we prolong the life of the amine, reduce maintenance costs, and enhance the overall performance of the separation process.

Ready to optimize your gas treatment processes? Get started with Reset’s amine treating solutions today. Whether you’re dealing with natural gas, flue gas, tail gas, acid gas, or syngas, our solutions are designed to utilize both generic and proprietary amine formulations. With a focus on flexibility, efficiency, and durability, we tailor our offerings to meet the dynamic needs of your industry. Don’t settle for less—choose Reset for cutting-edge technology and exceptional performance. Join the countless businesses already benefiting from our innovative solutions. Contact us now to elevate your gas treatment processes!

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges