Reset Energy excels in debottlenecking studies to optimize facility efficiency and productivity. The team’s comprehensive approach ensures that all aspects are thoroughly evaluated, leading to informed decisions and strategic actions for long-term success. Our experienced engineers identify bottlenecks, optimize processes, and provide cost-effective solutions, ensuring significant cost savings, improved performance, and enhanced sustainability for gas processing and alternative energy facilities. With their dedication to excellence and proven track record in the industry, Reset Energy’s engineers are trusted partners for advancing gas processing and alternative energy facilities towards greater efficiency and profitability.

Debottlenecking Features

Key Features that Set Us Apart

Ready to Optimize Your Plant?

Take the first step towards enhanced efficiency and reliability. Contact us today to schedule a consultation and discover how our debottlenecking services can transform your gas processing plant.

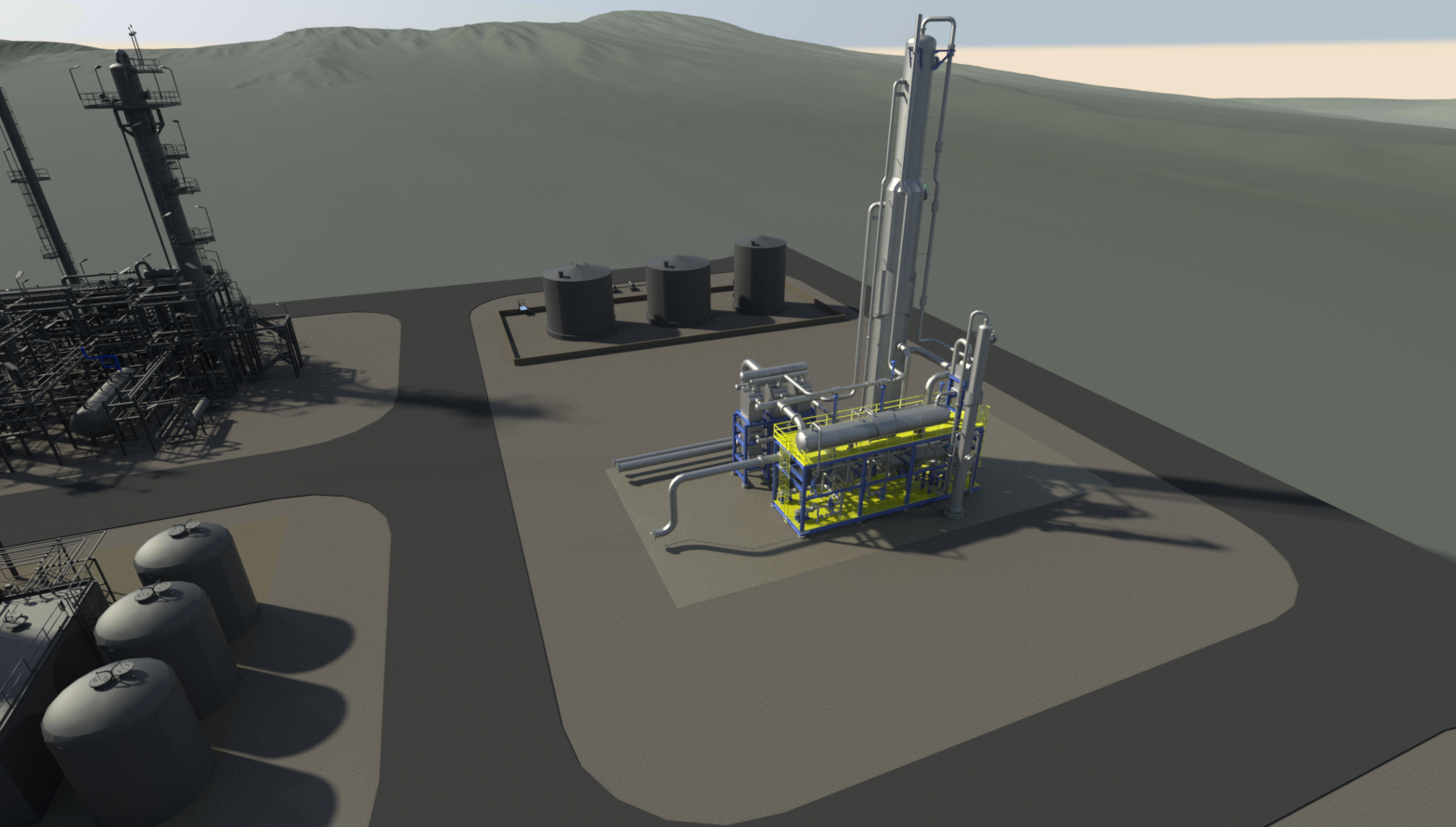

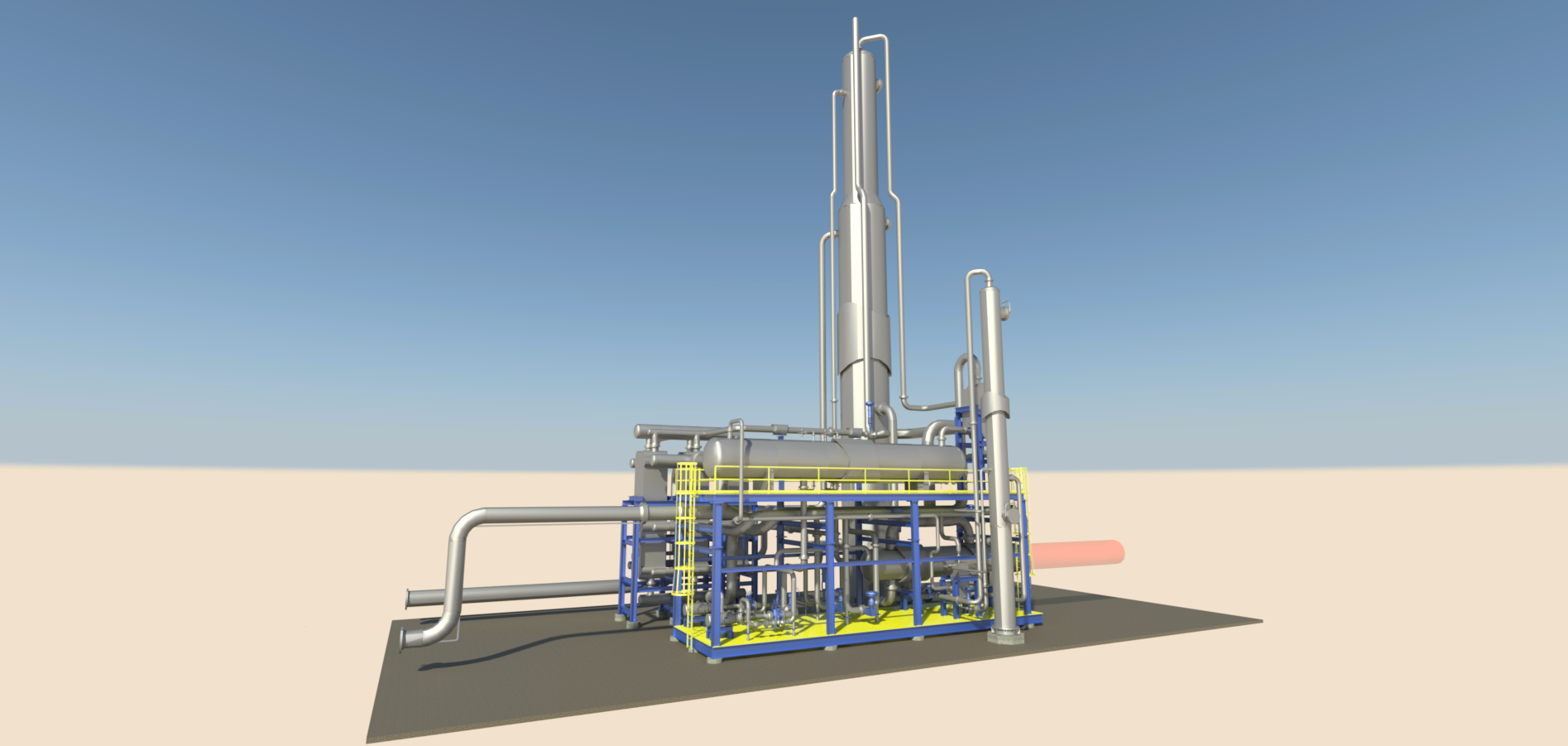

Our Projects

Two 400 GPM Amine Treaters, Two 2.5 MMBtu_Hr. TEG Dehydrators, One 5,000 BBL_D Condensate Stabilizer

10,000 BPD Stabilizer Package

1600 GPM Amine Treater Installation

Experience industry-leading reliability and performance as we redefine gas treatment standards. Explore our transformative solutions today. Innovative gas processing & treatment solutions that solve complex energy challenges