Mastering Gas Dehydration: An Essential Guide for Optimal Performance

Gas dehydration is a fundamental process in the oil and gas industry. It’s vital for ensuring the efficiency and safety of natural gas production, transportation, and storage. In this comprehensive guide, we’ll walk you through everything you need to know about gas dehydration. Whether you’re a seasoned professional or new to the industry, you’ll find valuable insights to help you make informed decisions.

Understanding Gas Dehydration

Gas dehydration is the process of removing water vapor from natural gas. Moisture in natural gas can lead to several issues, such as pipeline corrosion, hydrate formation, and reduced heating value. By removing water vapor, we ensure that natural gas is safe, efficient, and ready for use or further processing.

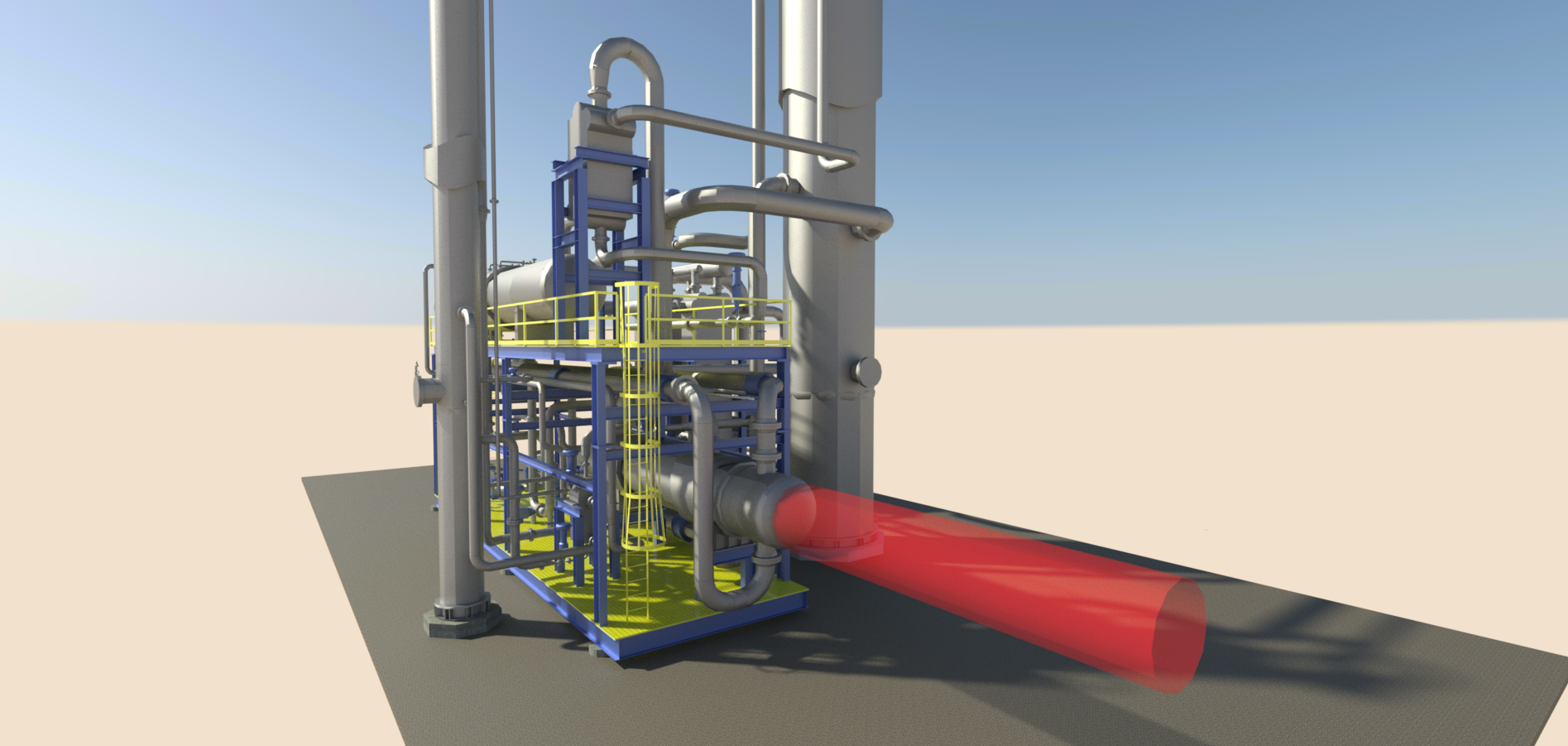

What Is a Gas Dehydration Unit?

A gas dehydration unit is a specialized system designed to extract water vapor from natural gas. These units come in various forms, but the most common types are glycol dehydration units and molecular sieve units. These systems play a crucial role in maintaining the quality and efficiency of natural gas.

A glycol dehydration unit usually consists of several key components:

How Do Gas Dehydration Units Work?

Understanding how gas dehydration units operate is essential for anyone involved in the natural gas industry. Here’s a step-by-step overview of how these systems function:

Absorbtion: In the absorption phase, natural gas enters the absorber tower and flows upward through a series of trays or packing material. A glycol solution, usually tri-ethylene glycol (TEG), flows downward, coming into contact with the gas. The water vapor in the gas is absorbed by the glycol, resulting in dehydrated gas exiting the top of the tower. The glycol solution, now containing water vapor, is sent to the regenerator tower for further processing.

Regeneration Phase: Once the glycol absorbs water vapor, it becomes saturated and needs to be regenerated. The glycol solution is pumped to the regenerator, where it is heated to remove the absorbed water. The water vapor is separated from the glycol and vented, while the regenerated glycol is cooled and returned to the absorber tower for reuse.

Heat Exchange: To improve efficiency, the wet glycol from the absorber tower is preheated by the hot, regenerated glycol in a heat exchanger. This reduces the energy required for the regeneration process and ensures that the system operates optimally.

Benefits of Using Gas Dehydration Units

Employing gas dehydration units offers several advantages for natural gas processing:

Enhanced Safety: By removing water vapor, gas dehydration units reduce the risk of pipeline corrosion and hydrate formation. This ensures that natural gas can be transported and stored safely without compromising infrastructure integrity.

Improved Efficiency: Dehydrated natural gas has a higher heating value, making it more efficient for combustion and other applications. This translates to cost savings and better performance for end-users.

Regulatory Compliance: Many regions have strict regulations regarding the moisture content in natural gas. Gas dehydration units help ensure compliance with these standards, avoiding potential fines and operational disruptions.

Reset Energy’s Gas Dehydration Solutions That Meet Your Goals

At Reset Energy, we are committed to providing our clients with the best possible solutions for their gas dehydration needs. Our units are designed with advanced technology and built using high-quality materials to ensure long-term reliability and performance.

Our TEG units are designed to minimize fuel usage and reduce pump maintenance, thanks to advanced heat exchangers and temperature control technology. These units efficiently remove water vapor, ensuring that your natural gas is safe and ready for use.

Our molecular sieve units offer a range of benefits, including selective adsorption, high adsorption capacity, regenerability, thermal stability, and cost-effectiveness. These units are perfect for separating gases and liquids, removing impurities, and maintaining high performance in high-temperature processes.

Reset Energy’s gas dehydration units stand out due to their:

Gas dehydration is a critical process for ensuring the safety, efficiency, and quality of natural gas. Understanding the components, operation, and benefits of gas dehydration units allows businesses to make informed decisions and optimize their operations.

At Reset Energy, we are dedicated to providing top-notch gas dehydration solutions that meet the needs of our clients. Whether you’re looking for TEG or molecular sieve units, we have the expertise and technology to help you achieve your goals.

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges