Reset Energy is committed to providing our clients with the best possible solutions for their gas dehydration needs. Our units are designed with advanced technology and built using high-quality materials to ensure long-term reliability and performance. We offer both tri-ethylene glycol (TEG) and molecular sieve units that are the perfect solution for separating gases and liquids, removing impurities, and maintaining high performance in high-temperature processes.

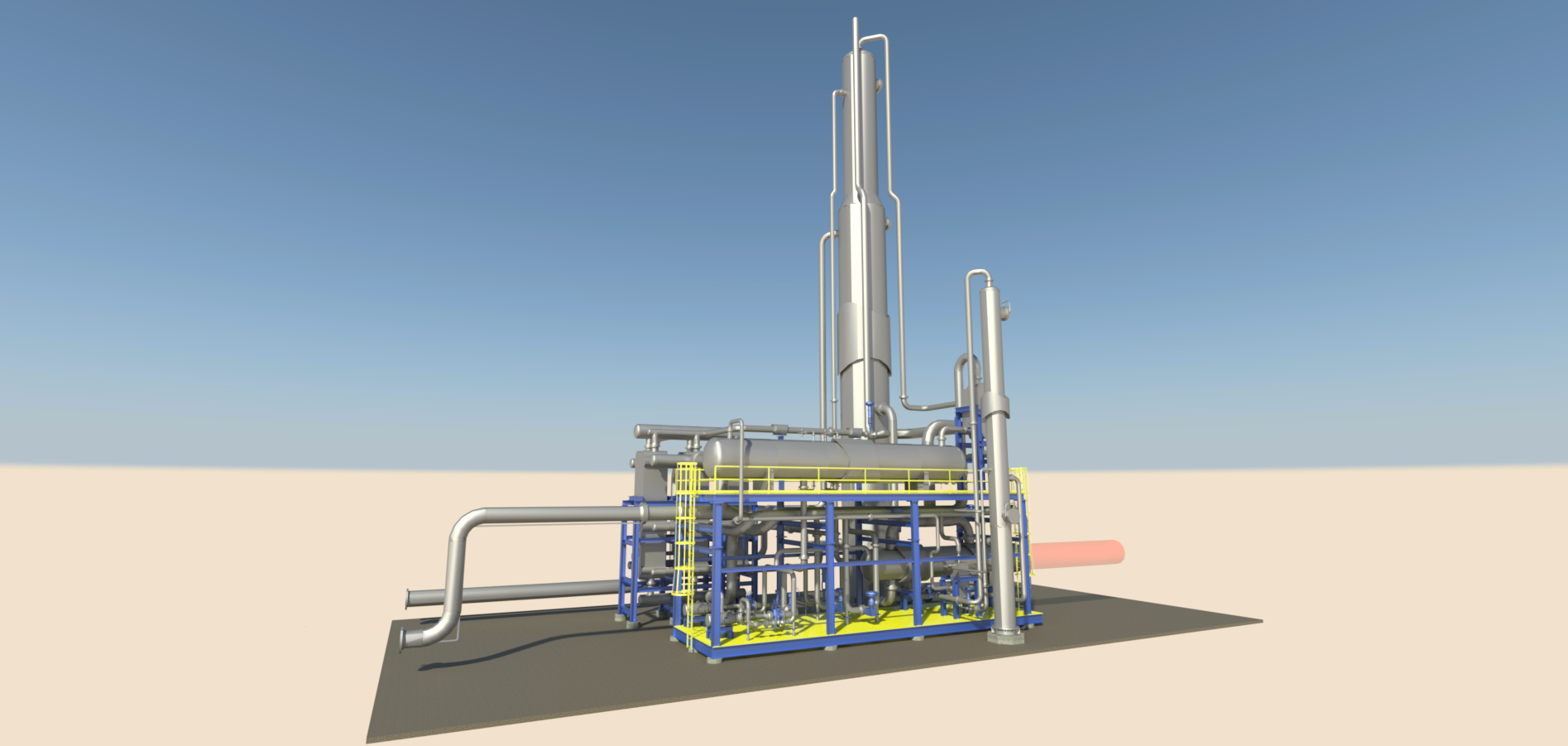

Our TEG units are designed to minimize fuel usage and reduce pump maintenance, thanks to advanced heat exchangers and temperature control technology. Our molecular sieve units offer a range of benefits, including selective adsorption, high adsorption capacity, regenerability, thermal stability, and cost-effectiveness. These units are the perfect solution for separating gases and liquids, removing impurities, and maintaining high performance in high-temperature processes.

Our TEG Unit Features:

Our Molecular Sieve Features:

Specifications to Suit Your Needs

Our Gas Dehydration Units come in a range of sizes and capacities to meet diverse operational needs:

- Up to 7.5 MMBTU per hour for NG or CO2 (TEG Units)

- Up to 300 MMSCFD flow rate

Key Features that Set Us Apart

Get Started with Our Gas Dehydration Systems!

Experience the difference that innovative, sustainable, and high-efficiency solutions can make. Let’s work together to enhance your gas treating process and achieve your operational goals.

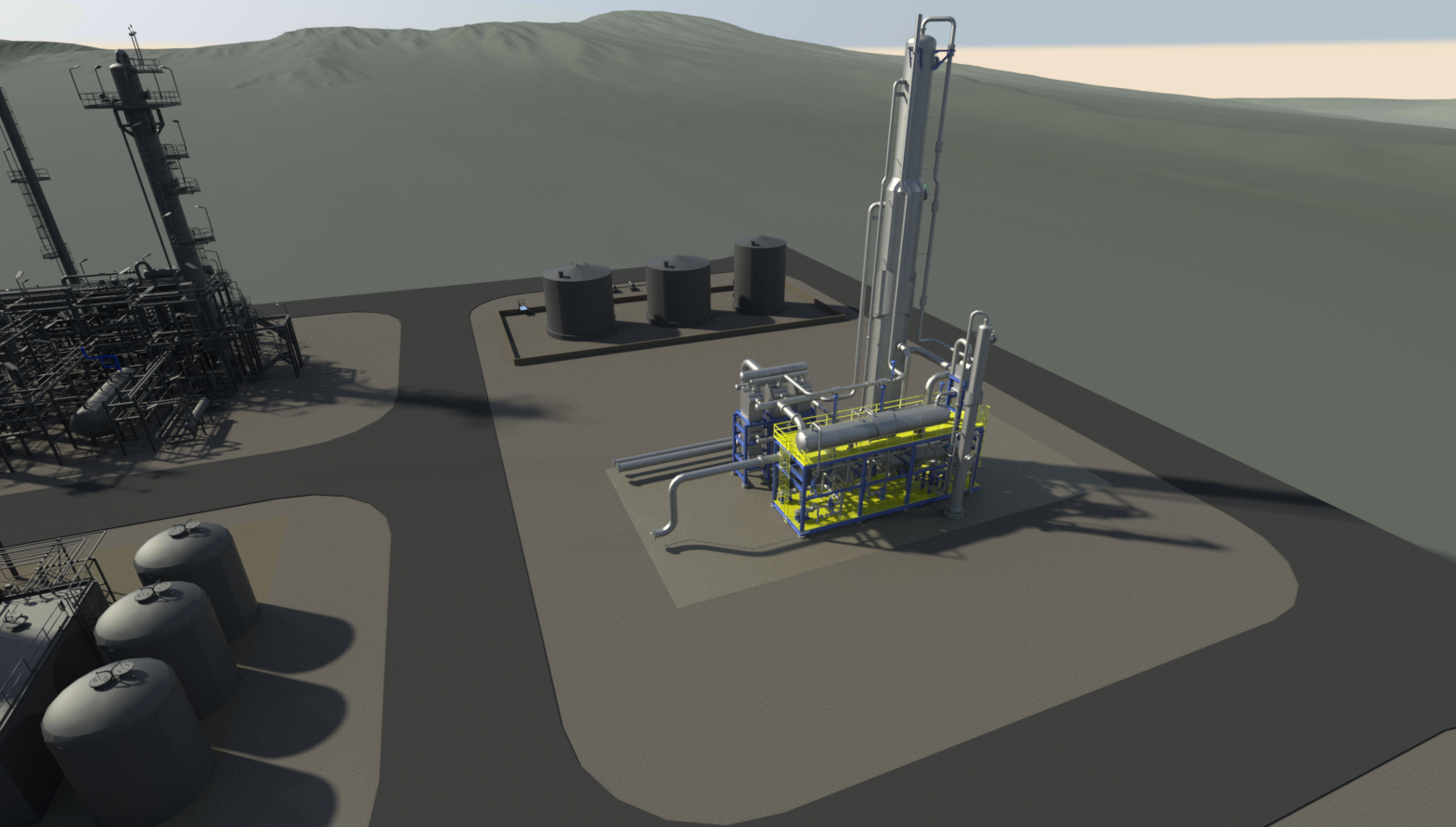

Our Projects

Two 400 GPM Amine Treaters, Two 2.5 MMBtu_Hr. TEG Dehydrators, One 5,000 BBL_D Condensate Stabilizer

1600 GPM Amine Treater, 3 MMBtu_Hr. TEG Dehydrator, 10,000 BBL_D Condensate Stabilizer

3 MMBtu_h TEG Regenerator

Experience industry-leading reliability and performance as we redefine gas treatment standards. Explore our transformative solutions today. Innovative gas processing & treatment solutions that solve complex energy challenges