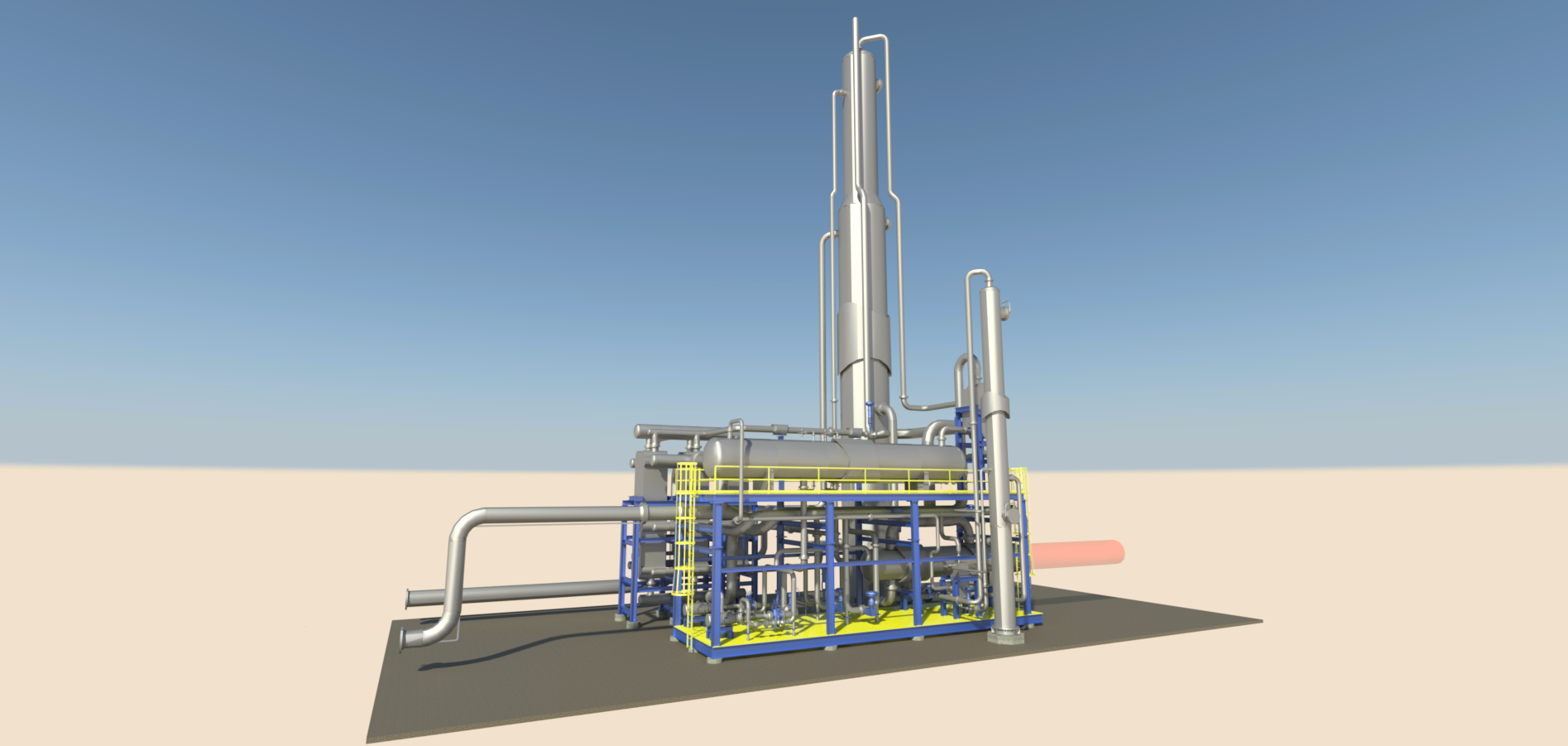

In the evolving landscape of gas processing, efficiency and adaptability are key. Our Nitrogen Rejection Units (NRUs) are designed to deliver top-tier performance, ensuring you get the most out of your feed gas while keeping costs under control. Our units use cryogenic distillation to effectively separate nitrogen from hydrocarbon streams. By leveraging a combination of compression, distillation, and multi-pass heat exchangers, our units achieve optimal separation, ensuring you get the highest quality output.

Single Column Cryogenic Distillation Features

Dual Column Cryogenic Distillation Features

Specifications to Suit Your Needs

Our Nitrogen Recovery Units come in a range of sizes and capacities to meet diverse operational needs:

- Small Capacity <5MMSCFD

- Modular Designs for up to 300MMSCFD

- Process Design Packages for large scale projects >300MMSCFD

Key Features that Set Us Apart

Get Started with Our Nitrogen Rejection Units!

Experience the difference that innovative, sustainable, and high-efficiency solutions can make. Let’s work together to enhance your gas treating process and achieve your operational goals.

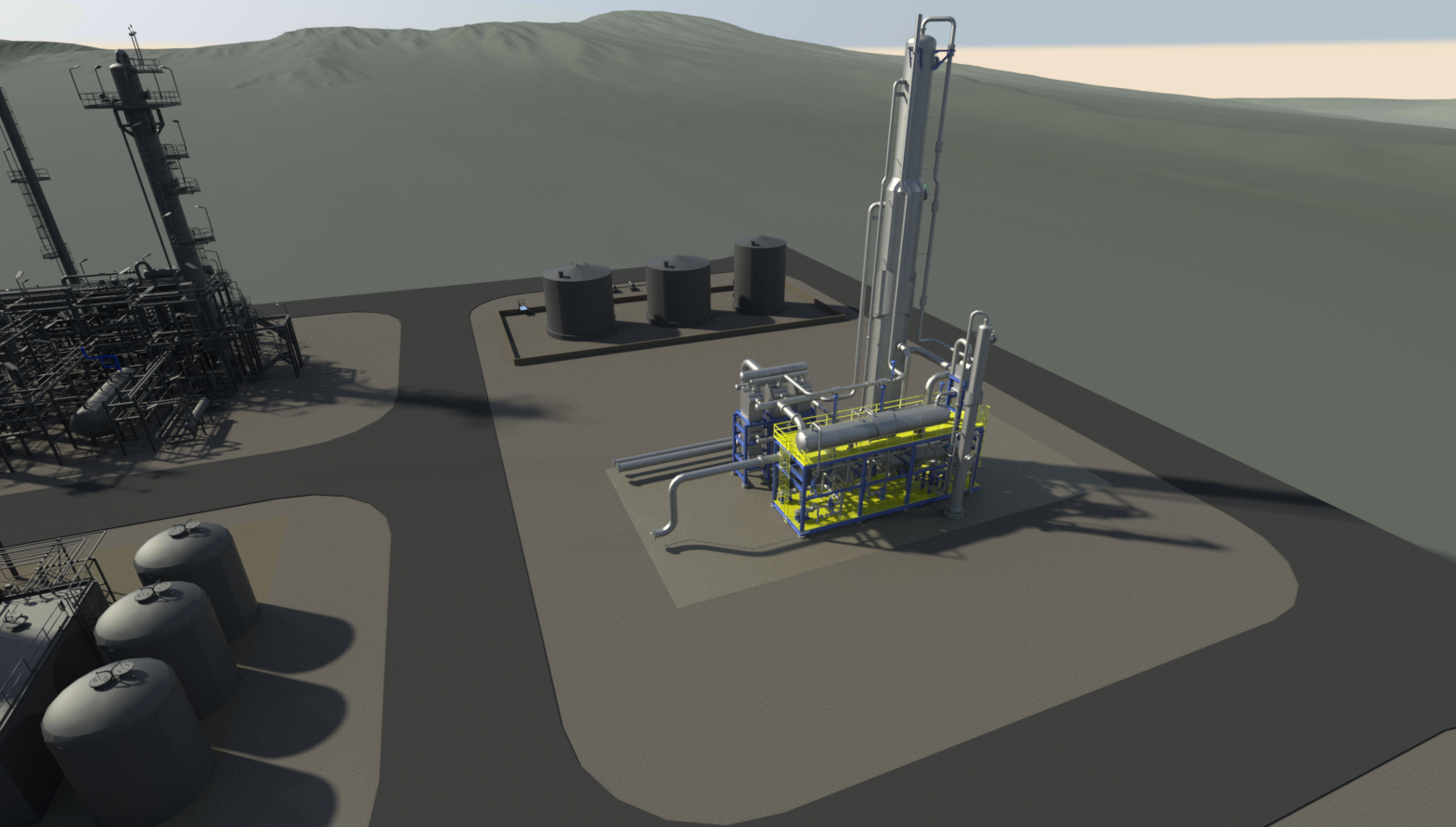

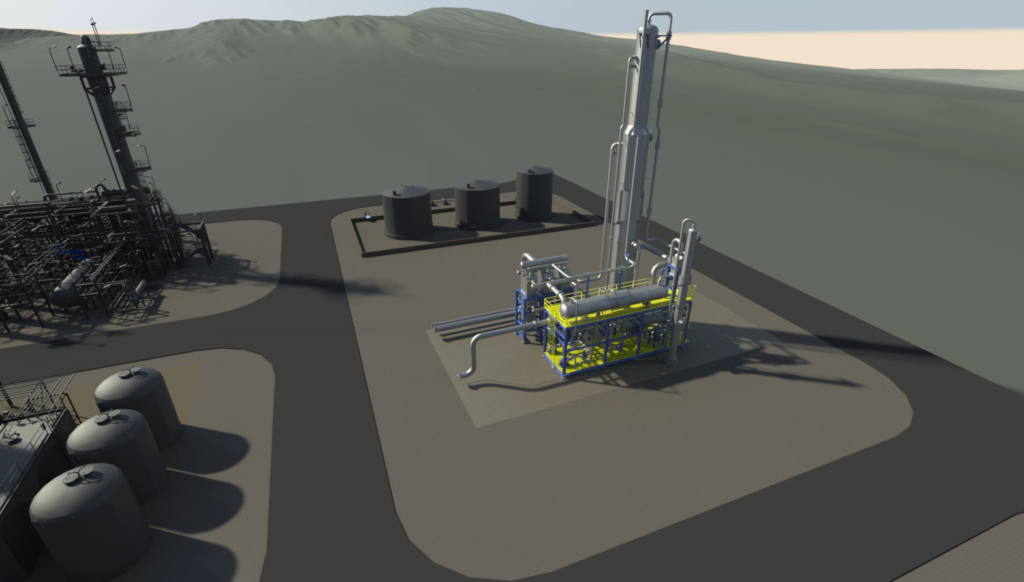

Our Projects

10,000 BPD Stabilizer Package

Two 400 GPM Amine Treaters, Two 2.5 MMBtu_Hr. TEG Dehydrators, One 5,000 BBL_D Condensate Stabilizer

3 MMBtu_h TEG Regenerator

Experience industry-leading reliability and performance as we redefine gas treatment standards. Explore our transformative solutions today. Innovative gas processing & treatment solutions that solve complex energy challenges