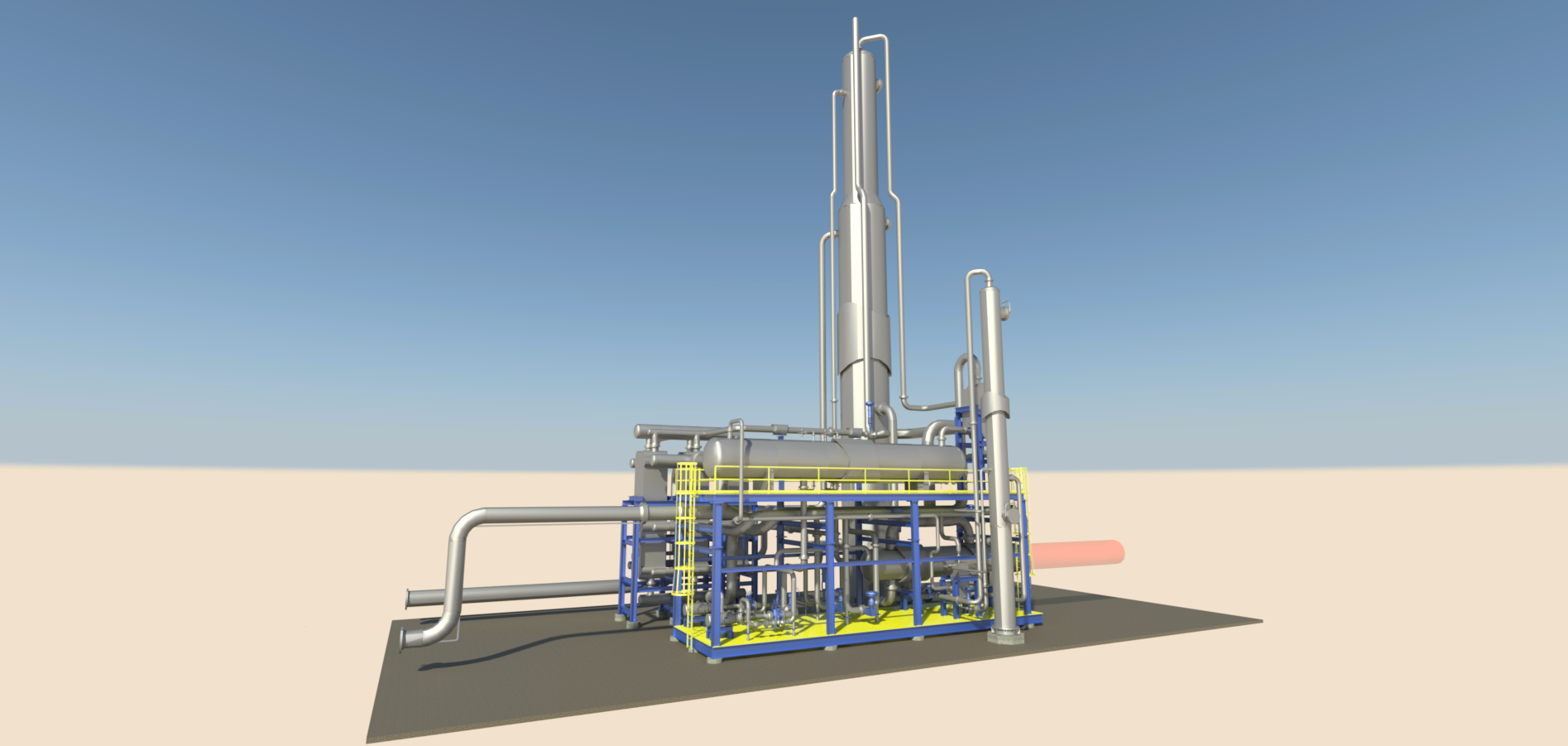

With increased focus on reducing global SO2 emissions, refiners and gas processors need proven sulfur recovery solutions to stay compliant with the toughest standards. Reset’s Sulfur Recovery Units (SRUs) utilize the Modified Claus process to recover up to 97% of the Hydrogen Sulfide (H2S) in their feed streams as molten elemental sulfur. When coupled with an amine-based tailgas cleanup unit (TGCU) and/or a sulfur dioxide (SO2) scrubbing system, our designs can achieve up to 99.9% sulfur recovery and SO2 emissions as low as 50 ppmv.

Reset understands that the key to low-cost, trouble-free sulfur plant lies in the small design details. We include features that minimize sulfur carry-over into catalyst beds, improve heat transfer at the inlet of the SRU Waste Heat Boiler, and simplify startup and shutdown.

Our expertise in piping design, fabrication and equipment specification enables us to identify and avoid issues that many designers and EPCs overlook. The result is sulfur recovery facilities that outperform and outlast our competitor’s offerings with uptimes more than 98% and service lives more than 40 years.

Sulfur Recovery Units Key Features

Specifications to Suit Your Needs

Our Sulfur Recovery Units come in a range of sizes and capacities to meet diverse operational needs:

- Capacity: 10 – 300 tons/day of sulfur product

- Recovery: 92.0 – 99.9% sulfur recovery

- SO2 emissions: As low as 50 ppmv (dry, 0% oxygen)

Key Features that Set Us Apart

Get Started with Our Sulfur Recovery Units!

Experience the difference that innovative, sustainable, and high-efficiency solutions can make. Let’s work together to enhance your sulfur recovery processes and achieve your operational goals.

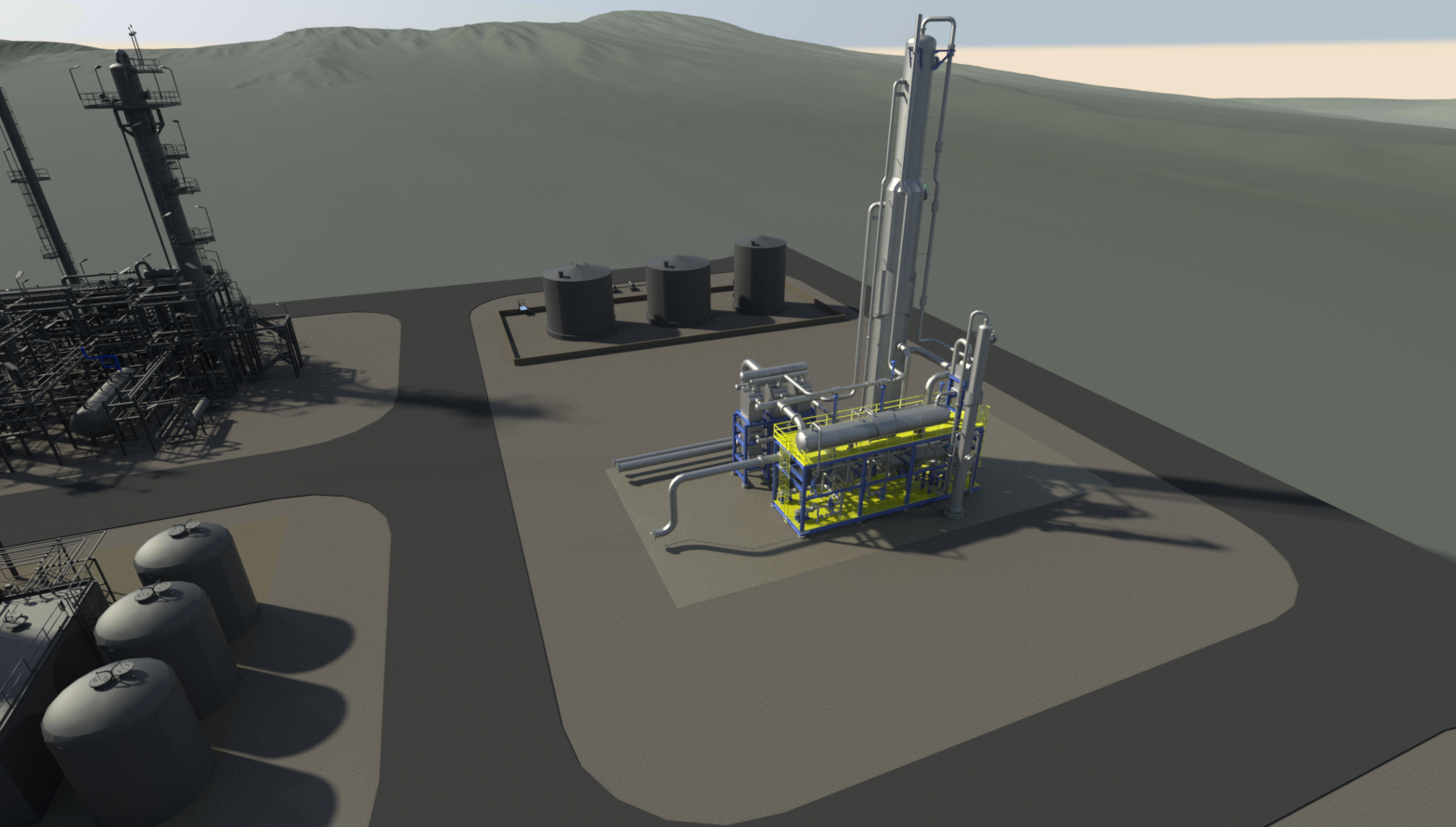

Our Projects

3 MMBtu_h TEG Regenerator

Two 400 GPM Amine Treaters, Two 2.5 MMBtu_Hr. TEG Dehydrators, One 5,000 BBL_D Condensate Stabilizer

1600 GPM Amine Treater, 3 MMBtu_Hr. TEG Dehydrator, 10,000 BBL_D Condensate Stabilizer

Experience industry-leading reliability and performance as we redefine gas treatment standards. Explore our transformative solutions today. Innovative gas processing & treatment solutions that solve complex energy challenges