Transforming Natural Gas with LNG Pre-Treatment & Production

Natural gas has revolutionized the energy landscape, providing a cleaner alternative to traditional fossil fuels. But did you know that the process of turning natural gas into Liquefied Natural Gas (LNG) involves a series of intricate steps to ensure its quality and safety? This blog post explores the fascinating world of LNG pre-treatment and production, shedding light on the technologies that make it all possible. Whether you’re a seasoned professional or just curious about how your fuel gets from the ground to your tank, this guide is for you.

Acid Gas Removal

Acid gas removal is crucial in the LNG production process. This technology focuses on eliminating carbon dioxide (CO2) and hydrogen sulfide (H2S) from natural gas. These compounds, if left untreated, can corrode equipment and create environmental hazards. Techniques such as amine absorption, physical solvent processes, and membrane separation are commonly used. These methods not only enhance the safety of the gas but also reduce the emission of pollutants and greenhouse gases.

Dehydration

Water is another impurity that must be removed from natural gas before it can be liquefied. Mole sieve dehydration packages are employed to extract water vapor from the gas stream. This step is vital as it prevents freezing during the liquefaction process. Additionally, removing water ensures that downstream equipment functions properly and eliminates the risk of failure during storage and transportation.

Mercury Removal

Mercury, though present in trace amounts, poses significant risks in LNG production. Adsorption and absorption technologies are deployed to extract this toxic element from the gas stream. Effective mercury removal safeguards equipment from damage and ensures the safety of plant operators.

Nitrogen Removal

Nitrogen, while not harmful, can dilute the energy content of LNG. Cryogenic technologies are used to separate nitrogen from natural gas, improving the purity and quality of LNG. This step is essential for meeting industry standards and reducing energy consumption during liquefaction.

Liquefaction

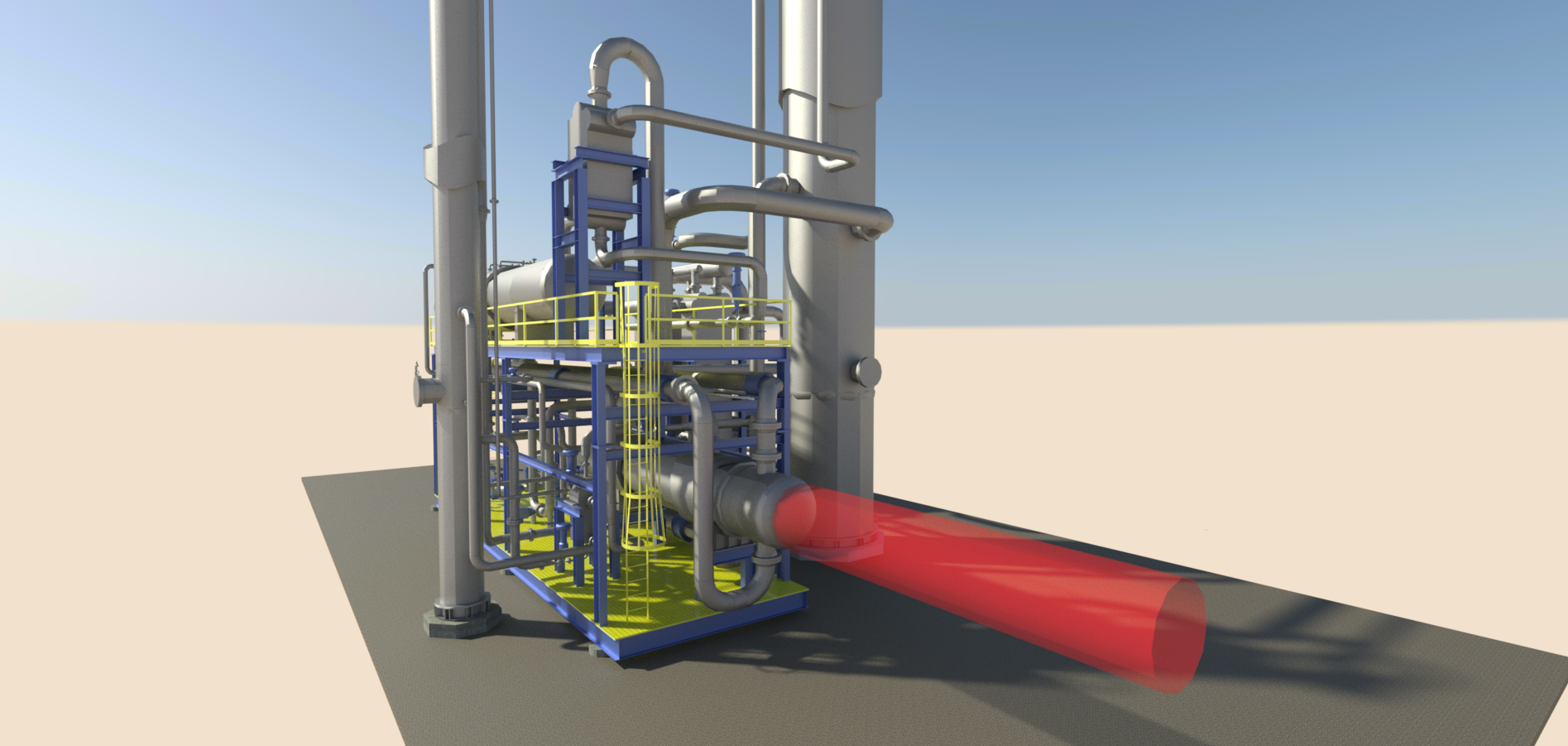

The final and most critical step in LNG production is liquefaction. This process involves cooling natural gas to -162°C, transforming it into a liquid state. Small-scale LNG liquefaction packages cater to niche markets, while mid-to large-scale projects require more comprehensive solutions. Effective liquefaction minimizes power requirements and operational complexity, making the entire process more efficient.

LNG Pre-Treatment & Production Processes Explained

Let’s dive into each of the critical processes involved in LNG pre-treatment and production and explore the purpose and benefits of acid gas removal, dehydration, mercury removal, nitrogen removal, and liquefaction. Each process will be outlined with an overview of its function and how it contributes to the overall efficiency and safety of LNG production. This comprehensive look will provide a clearer understanding of the technologies that transform natural gas into a viable, clean-burning fuel.

Acid Gas Removal: The primary aim of acid gas removal is to eliminate CO2 and H2S from natural gas. These gases can cause corrosion in pipelines and storage tanks, leading to potential leaks and hazards. Amine absorption involves passing natural gas through a liquid amine solution that absorbs acid gases. Physical solvents work similarly but use non-reactive liquids. Membrane separation utilizes selective membranes to filter out specific gases. Adhering to industry standards ensures that the treated gas meets safety and environmental regulations. This technology is widely used in natural gas processing plants and LNG facilities.

Dehydration: Dehydration removes water vapor, preventing ice formation during liquefaction and ensuring the smooth operation of downstream equipment. Mole sieve dehydration employs synthetic zeolites to absorb water molecules from the gas stream. This process is highly efficient and can achieve very low moisture levels. Meeting industry standards in dehydration is crucial for preventing equipment failure and maintaining the quality of LNG. This technology is essential in both small and large-scale LNG operations.

Mercury Removal: Removing mercury is vital for protecting equipment and ensuring the safety of plant operators. Even trace amounts of mercury can pose significant risks. Adsorption uses materials like activated carbon to capture mercury from the gas stream. Absorption involves chemical reactions that permanently remove mercury compounds. Strict industry standards govern mercury removal to prevent environmental contamination and equipment damage. This technology is indispensable in modern LNG plants.

Nitrogen Removal: Nitrogen removal enhances the energy content and quality of LNG, making it more efficient and valuable. Cryogenic distillation separates nitrogen by cooling the gas mixture to very low temperatures, allowing nitrogen to be condensed and removed. Ensuring that LNG meets industry standards for nitrogen content is crucial for its commercial viability. This technology is widely applied in large-scale LNG production.

Liquefaction: Liquefaction transforms natural gas into a more compact liquid form, facilitating storage and transportation. The gas is cooled in stages using refrigeration cycles until it reaches -162°C. It is then stored in insulated tanks to maintain its liquid state. Meeting liquefaction standards ensures safety and efficiency in LNG production. This technology is central to the global LNG supply chain.

LNG Technologies Contribute to a Sustainable Future

LNG pre-treatment and production are vital for the energy industry. By employing advanced technologies like acid gas removal, dehydration, mercury removal, nitrogen removal, and liquefaction, the LNG industry ensures the quality and safety of its products. These advancements not only contribute to a more sustainable energy future but also provide reliable and efficient solutions for the global energy market.

For industries looking to stay ahead in the energy sector, investing in these technologies is crucial. Reset Energy offers a suite of LNG pre-treatment and production technologies that optimize the LNG process and ensure the quality of the final product. Explore further to understand how Reset and LNG can revolutionize your energy solutions and bring about a cleaner, more efficient future.

Plan an introduction meeting today

Contact our experts today to discover how our innovative solutions can tackle your complex energy challenges